Organ-on-chip

made easy.

Dive into the next gen in vitro microfluidic platforms ›

Microfluidic chips, systems and accesories

MICROFLUIDIC FLOW CONTROL SYSTEM

Pressure-based systems that match your chips.

Product categories

Product categories

Featured products

More products ›

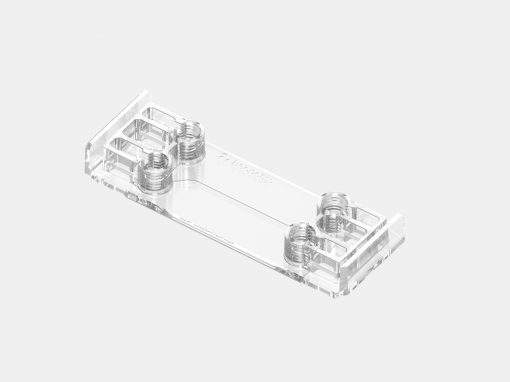

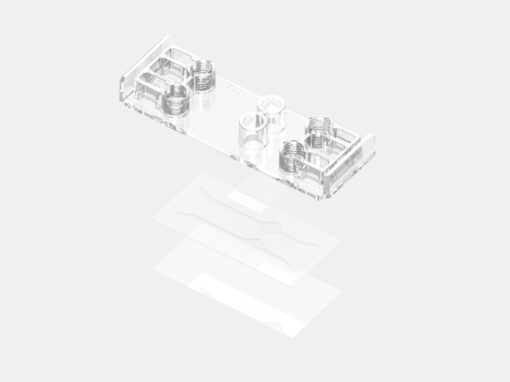

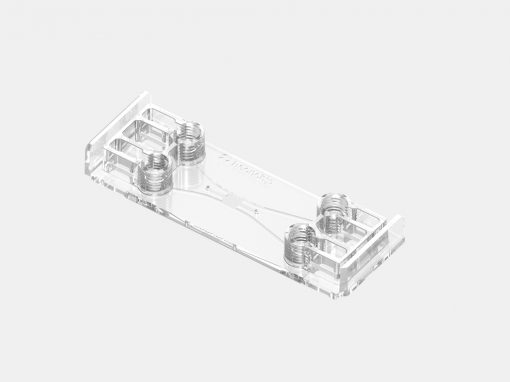

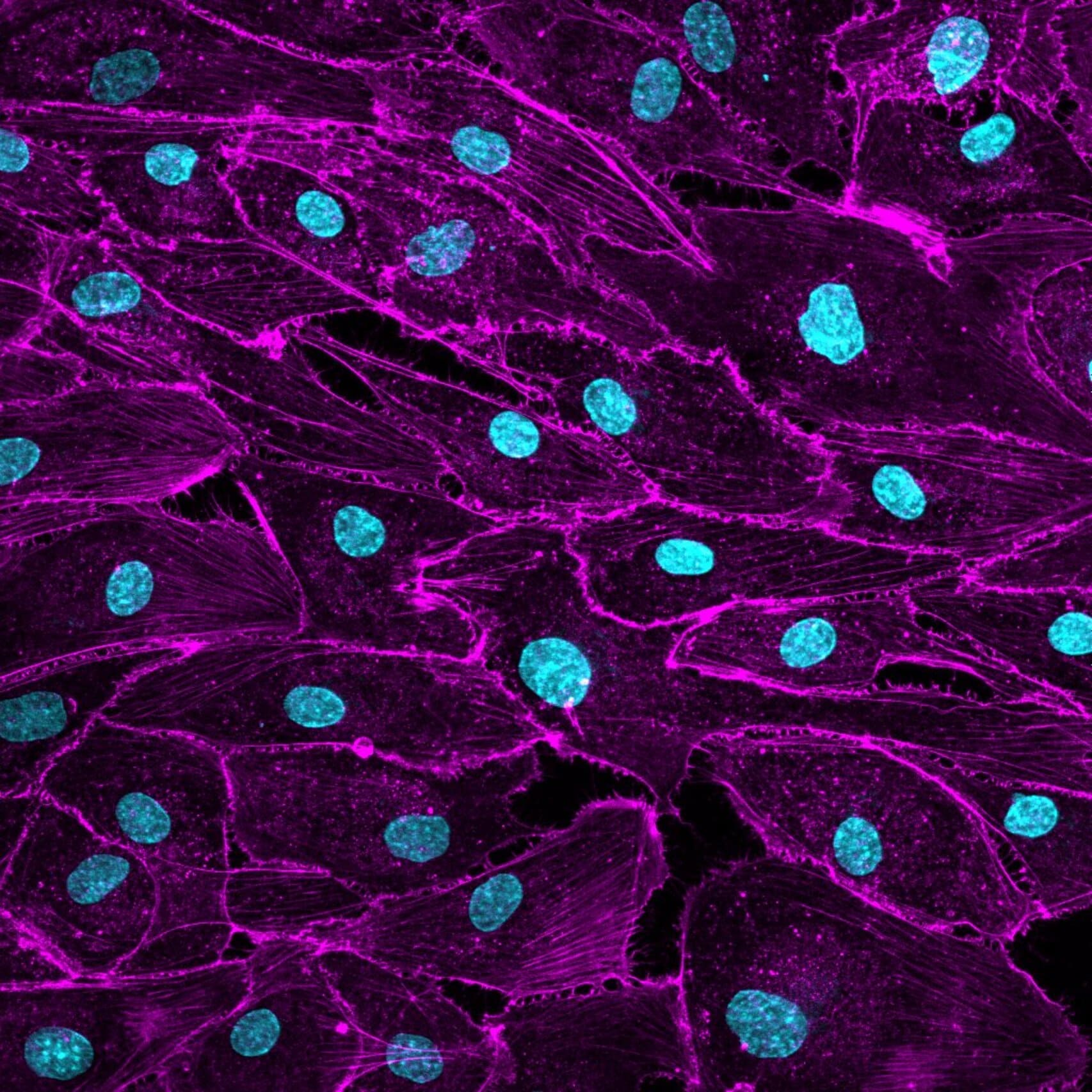

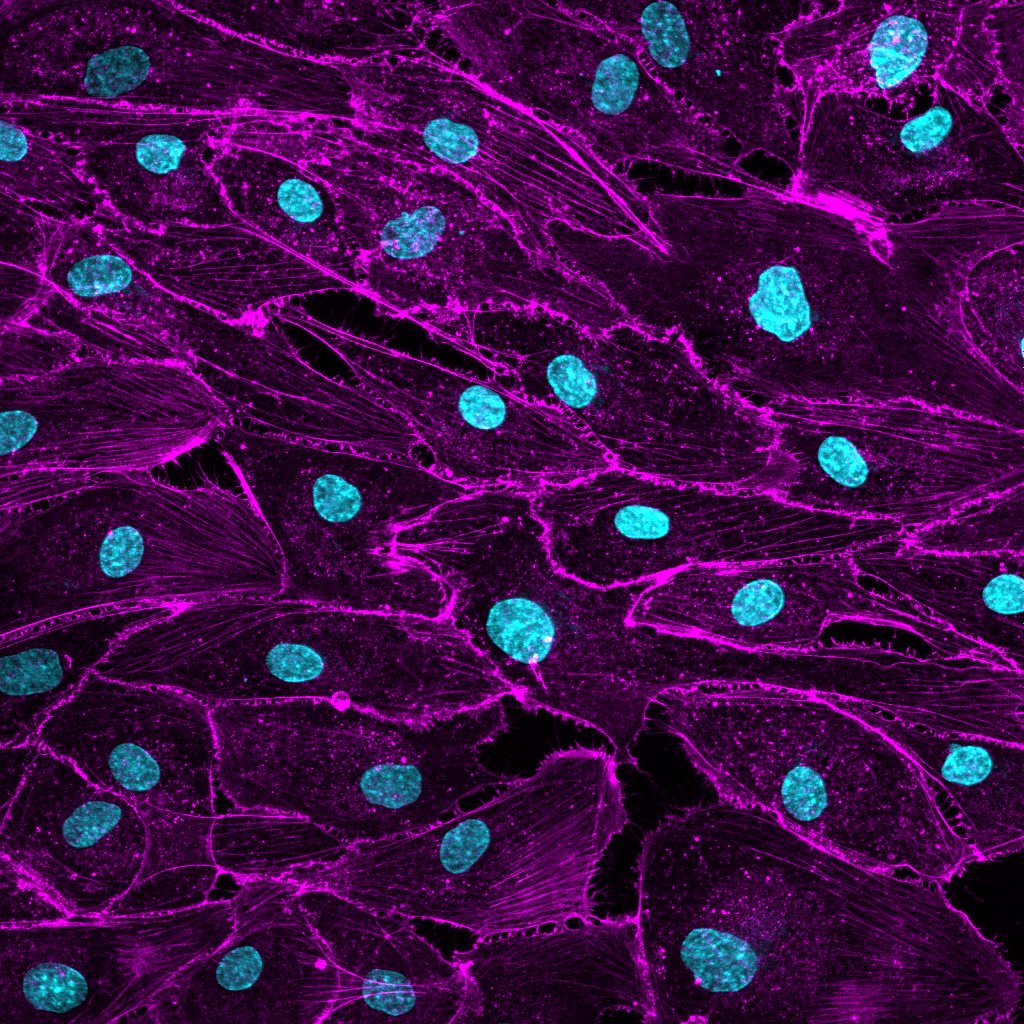

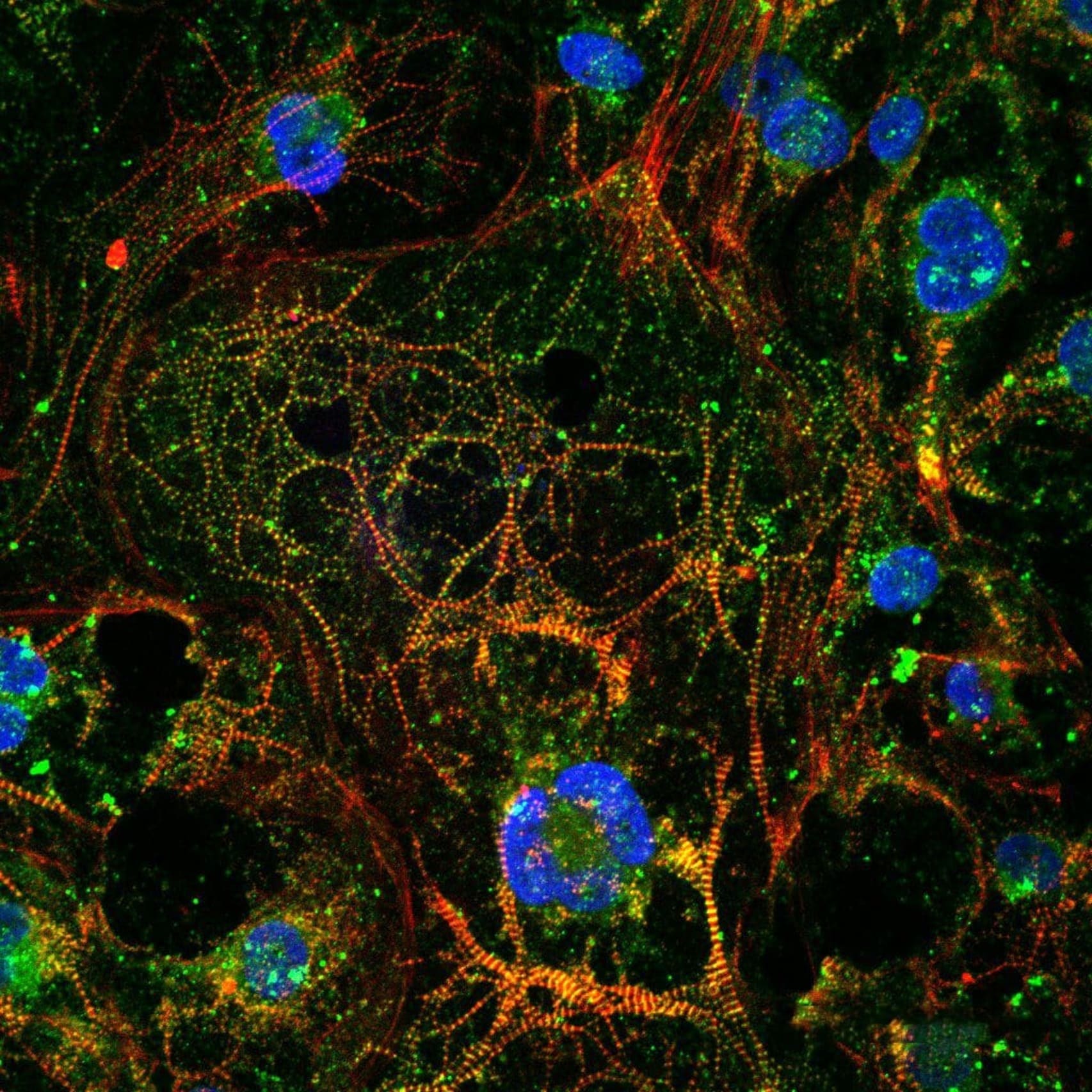

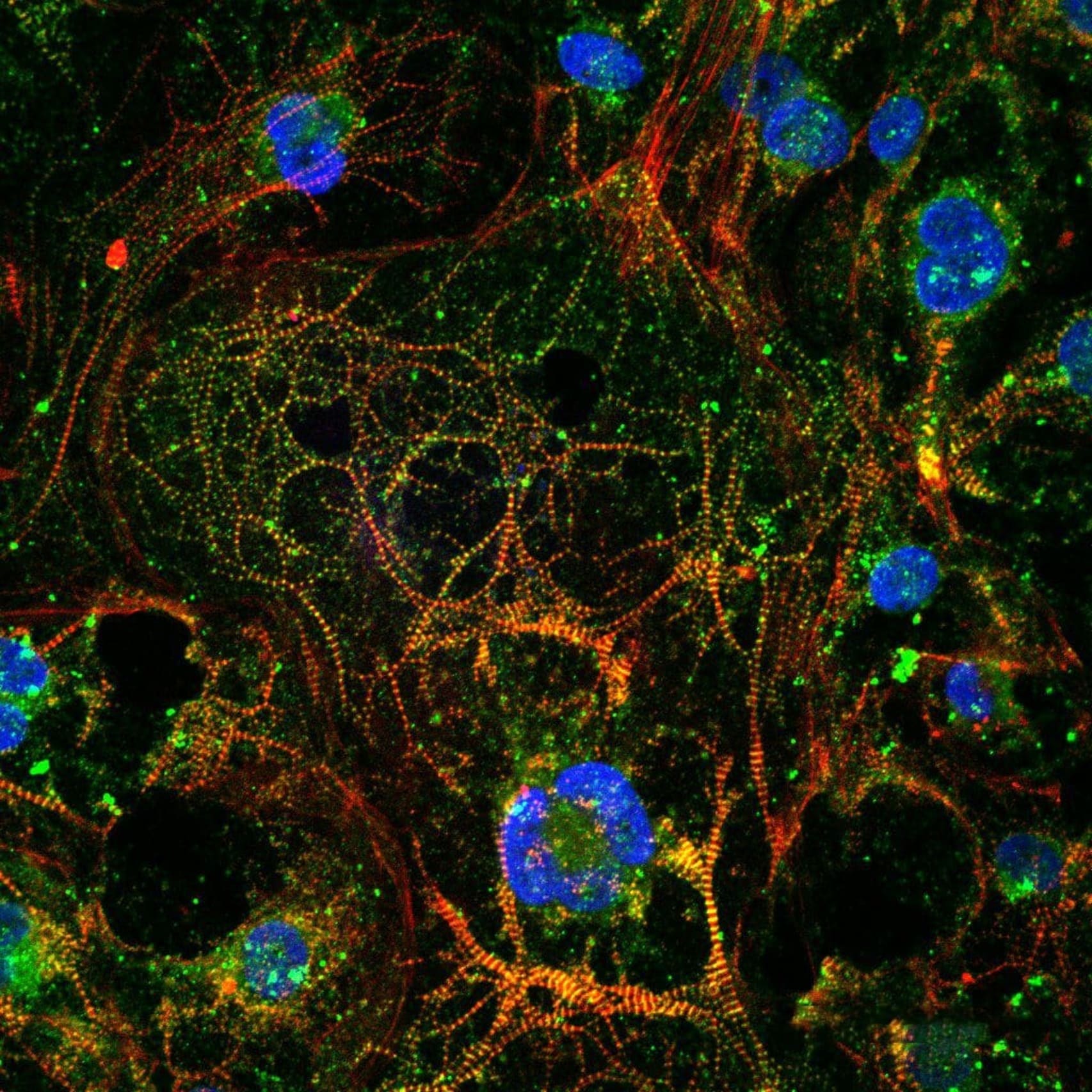

Organ-on-chip technology

Our devices are designed for maximum ease of use and versatility. Made from optimal plastic materials for life sciences applications.

Our Organ-on-chip Technology

Our devices are designed for maximum ease of use and versatility. Made from optimal plastic materials and life sciences applications.

Latests posts

All post ›

Microfluidic consultancy services for biological applications

We accompany you on the path from the idea to the mass production of your microfluidics projects for biological applications.

Microfluidic consultancy services

We accompany you on the path from the idea to the mass production of your microfluidics projects for biological applications.

Latests publications

Journal of Hazardous Materials 2025, 486, p. 136965.

Small 2025, 21(9).

Bioengineering & Translational Medicine 2025

Journal of Hazardous Materials 2025, 486, p. 136965.

Small 2025, 21(9).

Bioengineering & Translational Medicine 2025

All publications ›

Projects

Awards