Summary

This technical note intends to give a summary of the three most used perfusion systems in organ-on-chip research: syringe pump, peristaltic pump and pressure-based systems.

Syringe Pump

The syringe pump is one of the most used perfusion systems. It is a laboratory instrument designed to move fluid from a syringe into a system with high precision. It operates by mechanically advancing (or retracting) the syringe plunger at a controlled rate, enabling accurate and reproducible fluid delivery.

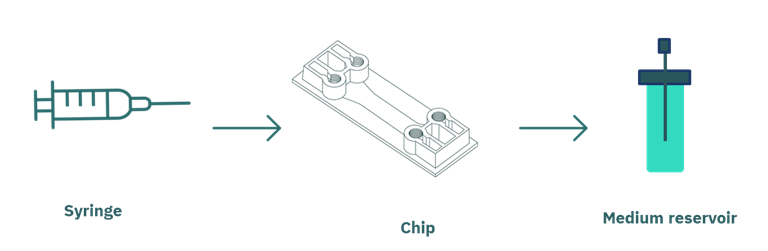

Figure 1 Scheme of a one-direction fluidic circuit using a syringe pump. The cell culture medium leaves the syringe, passes through the chip and reaches the medium reservoir.

Advantages

- High precision, accuracy and stability in fluid delivery.

- Linear flow.

- Programmable flow profiles.

- Reproducibility across experiments due to automated control.

- Wide range of flow rates possible depending on syringe size and motor resolution.

- Bidirectional operation (infusion and withdrawal modes available).

- Compatible with temperatures up to 40ºC.

Disadvantages

- Limited total volume (restricted to the syringe size being used).

- No recircularization but injection and withdrawal modes (bi-directional).

- Manual syringe replacement required when volume runs out – interrupts long experiments.

- Higher flow rates with unidirectional flow limit experimental duration

Figure 2 Photo of a fluidic circuit using Infusitek© syringe pump.

Solution for recirculation

One major disadvantage of using syringe pumps for Organ-on-a-Chip systems is their lack of natural medium recirculation. This limitation restricts long-term/high flow-rate experiments and prevents unidirectional closed-loop perfusion. However, it can be overcome by adding a microfluidic recirculation valve to the circuit. The valve redirects the fluid paths and allows the medium to return to the syringe for continuous reuse. As a result, the system can maintain recirculating flow without manual intervention. In addition, the device still experiences a fully unidirectional flow. This is possible because the valve ensures that fluid always enters and exits the chip in the same direction. Therefore, the chip does not experience bidirectional flow, even when the pump switches between infusion and withdrawal modes. Ultimately, this setup increases experimental runtime while preserving stable and physiologically relevant flow conditions.

When to choose a Syringe Pump for Organ-on-chip experiments

Syringe pumps are an excellent choice for many microfluidic and organ-on-chip applications, particularly when simplicity and precision are key. They work well in the following scenarios:

- Short-term unidirectional experiments: For assays lasting a few hours to several days, syringe pumps deliver stable, consistent flow without the need for complex feedback systems.

- Bidirectional or recirculating flow studies: When paired with a valve or in infusion-aspiration mode, they can simulate physiological shear cycles or nutrient exchange.

- Experiments with circulating cells or particles: They support dynamic cell–cell or cell–particle interactions.

- Quick and easy setup: Syringe pumps are straightforward to assemble and operate—perfect for labs seeking a low-barrier entry into microfluidic perfusion.

- Multi-channel operation: Parallel microfluidic chips can be operated simultaneously by using multiple syringe heads on the same pump system or by connecting several pumps in parallel.

- Budget-friendly systems: Their affordability makes them a go-to option for academic or early-stage R&D labs.

- High precision at low flow rates: Suitable for applications requiring steady, few microliter-scale flow.

Peristaltic pumps

A peristaltic pump is a type of positive displacement pump that moves fluid through a flexible tube using a rotating mechanism with rollers. As the rollers compress and release the tubing in a wave-like motion (similar to peristalsis in the digestive system), the fluid is pushed forward in a controlled manner without the liquid ever contacting the pump’s internal components.

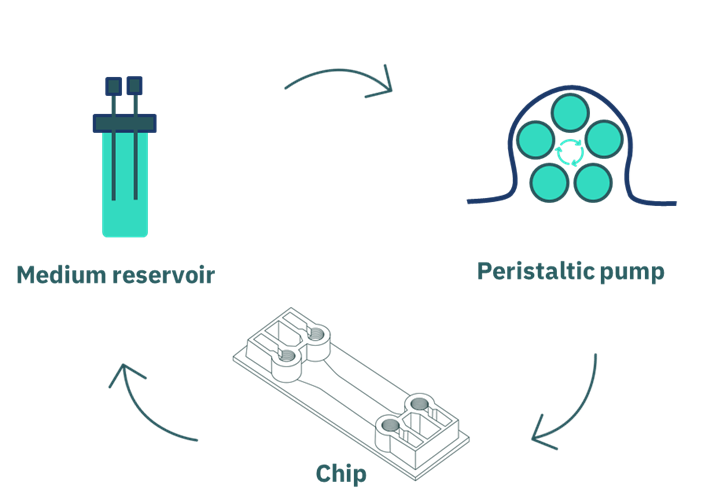

Figure 3 Scheme of a recirculating circuit using a peristaltic pump. The cell culture medium leaves the medium reservoir, passes through the peristaltic pump into the chip, and leaves the chip to return to the medium reservoir.

Advantages

- Recirculating flow: Can operate for long periods without interruption (unlike syringe pumps that need refilling).

- In a recircularized circuit, only one medium reservoir is needed, decreasing the volume of cell culture medium necessary for the duration of the culture.

- Scalable: Easily adaptable from small benchtop experiments to multi-channel perfusion and long-term cell culture systems, supporting both single and parallel culture setups.

- Bidirectional flow in each channel, changing the direction of movement of the rollers.

- Easy to operate.

- Budget-friendly option.

Disadvantages

- Lower precision and accuracy compared to syringe pumps due to pulsatile flow inherent to roller action (though dampeners can reduce this).

- Tubing wear: tubing fatigues over time, requiring replacement.

- Flow rate depends on tubing internal diameter, rollers and motor speed, so ultra-low flows are harder to achieve.

- Not compatible with the circulation of cells and/or particles since the rollers can damage them.

Figure 4 Photo of a recirculating circuit using a Masterflex© peristaltic pump.

When to choose a Peristaltic Pump for Organ-on-chip experiments

Peristaltic pumps are a strong choice for continuous and long-term Organ-on-Chip perfusion systems, particularly when you need recirculating flow and culture medium exchange without the need for external valves. They’re well-suited to the following applications:

- Long-term, continuous perfusion: Ideal for experiments running over several days or weeks.

- Recirculating flow systems: Perfect for closed-loop configurations where culture medium or blood analogue must be continuously cycled between reservoirs and chips.

- Multi-chip or parallel setups: Easily drives flow through several chips at once.

- Shear stress and mechanical stimulation studies: Offers stable, pulsation-like flow patterns that can better mimic physiological conditions.

- Scalable and flexible operation: Compatible with a wide range of flow rates and tubing sizes, allowing quick adaptation to different chip formats.

- User-friendly and low-maintenance: Simple to operate with minimal calibration, ideal for routine or automated use in incubator environments.

Pressure-based Systems

A pressure-based pump is a fluid delivery system that uses pressurised gas (commonly air or nitrogen) to drive liquid from a reservoir through tubing or microfluidic channels. Instead of mechanically displacing liquid with a piston or rollers, the applied gas pressure pushes the liquid forward, enabling smooth, continuous flow.

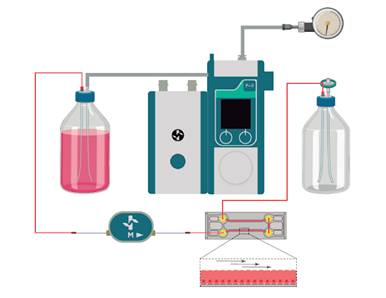

Figure 5: Scheme of a fluidic circuit using a pressure-based pump. The liquid leaves the medium reservoir, passes through the flow control unit, enters the chip, and then travels to another medium reservoir.

Advantages

- Pulse-free, smooth flow: they provide continuous, stable liquid delivery.

- Precise control: flow can be finely tuned by adjusting applied pressure.

- Modular system that can support multiple channels: a single pressure source can drive flow through several reservoirs in parallel.

- Fast response time: immediate changes in pressure translate into quick flow adjustments.

- Possible to record the flow rates and pressure applied over time.

- Recirculation is possible by adding valves to the circuit.

Disadvantages

- Flow rate depends on system resistance (tubing length, channel geometry, viscosity), which can make calibration complex.

- Sometimes requires external gas supply (compressed air, nitrogen) and regulators, which increase setup complexity and cost.

- Limited to pressurizable reservoirs: special containers are needed to withstand pressure.

- Setup can be bulky compared to other pumps.

- Safety considerations: pressurized systems must be handled carefully to avoid accidents.

- Less intuitive system to operate.

- More expensive to perform high-throughput experiments.

Figure 6 Photo of a fluidic circuit using Fluigent© pressure-based pump.

When to choose a Pressure-based system for Organ-on-chip experiments

Pressure-driven systems are the gold standard for precise and stable flow control in advanced Organ-on-a-Chip and microfluidic platforms. They are ideal for experiments that demand high accuracy, responsiveness, and parallelization.

- High-precision flow control: Offers ultra-stable, pulsation-free flow—ideal for shear-sensitive cells such as endothelial or epithelial layers.

- Fast response and dynamic control: Enables rapid flow rate adjustments, suitable for simulating physiological events or performing real-time flow modulation.

- Live monitoring and data recording: Flow rates and applied pressures can be continuously monitored and logged throughout the experiment, providing valuable datasets for reproducibility, validation, and process optimization.

- Long-term, stable operation: Provides consistent perfusion over extended culture periods without refills if paired with a valve.

- Integration with automation and sensors: It is not exclusive of pressured-based systems, but most circuits come linked to flow sensors, valves, and control software for automated feedback and data logging.

- Compatible with high-throughput or multi-organ systems: Supports complex organ-on-a-chip networks with independent flow control in each organ compartment.

| Feature / Criteria | Syringe Pump | Peristaltic Pump | Pressure-Based Pump |

| Operating principle | Motor-driven linear displacement of a syringe plunger | Rollers compress flexible tubing to push fluid | Pressurized gas drives liquid from a reservoir |

| Flow smoothness | Generally smooth, slight pulsation at very low rates | Pulsatile due to roller motion | Pulse-free, continuous flow |

| Flow rate precision | Very high | Moderate | High (pressure-dependent) |

| Volume capacity | Limited by syringe and reservoir size | Continuous (not volume-limited) | Depends on reservoir size |

| Low flow capability | Excellent | Limited | Excellent |

| Fluid contact | Syringe and tubing | Tubing only | Reservoir and tubing and flow unit |

| Ease of setup | Simple | Simple–moderate | More complex |

| Multi-channel operation | Possible with multiple syringe heads | Possible with multiple pump heads | Possible with a pressure controller connected to several reservoirs |

| Cost | Low-Moderate | Low–moderate | High |

More Information

Based on the advantages and limitations discussed above, choosing the right perfusion system depends on your specific experimental needs. To support a wide range of research applications, we offer perfusion solutions based on all three pumping technologies.

For syringe pump systems, we distribute products from Infusetek. For peristaltic pump solutions, we provide systems from Masterflex. For pressure-based perfusion systems, we are authorized distributors of Fluigent.

If you have any questions or would like help selecting the most suitable system for your application, feel free to contact us through this section or write to us by email at info@beonchip.com.