Services

Bringing your microfluidics ideas to life, from design to large-scale production.

Applications

We are a multidisciplinary team with more than 15 years of experience in the field of microtechnologies, microfluidics and cell culture. We work in close collaboration with the customer to identify the application needs and translate them into specifications of the microfluidic device.

- Custom Organ-on-chip platforms

- Cell culture platforms

- Biology lab instrumentation

- OEM and ODM for the life science industry

From idea to production

01. Idea

We work in close collaboration with the customer to identify the application needs and translate them into specifications of the microfluidic device.

02. Design

We help you streamline your previous designs and prepare them for mass production. Our team generates 2D and 3D renders of the new design and produce the first proves of concept with different materials before prototyping the full device.

03. Prototype

We manufacture high resolution prototypes in short deadlines to identify design improvement points. We can make short runs of your devices for using We have the wide variety prototyping tools and materials at our disposal.

04. Validation

We can perform microfluidic tests and biological validations in our facilities.

05. Industrialization

Once the prototype has been validated, we are ready to take your prototype to mass production using thermoplastic injection or micromachining. We can assist you in the mold design, injection parameter optimization and take care of all the services you might need afterwards: injection, assembly, sterilization and packaging.

Facilities and capabilities

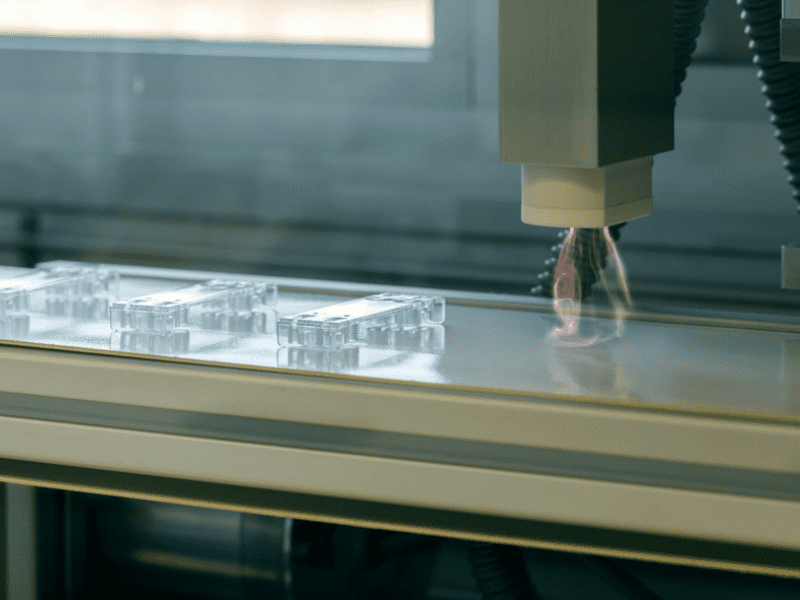

Chip prototyping

We specialize in microfabrication for biological applications. Our capabilities include, 2D plastic layer definition, laser cutting, plastic bonding by chemical and thermal bonding methods, surface functionalization and sterilization. Tell us your idea for a microfluidic device and we will help you bring them to life.

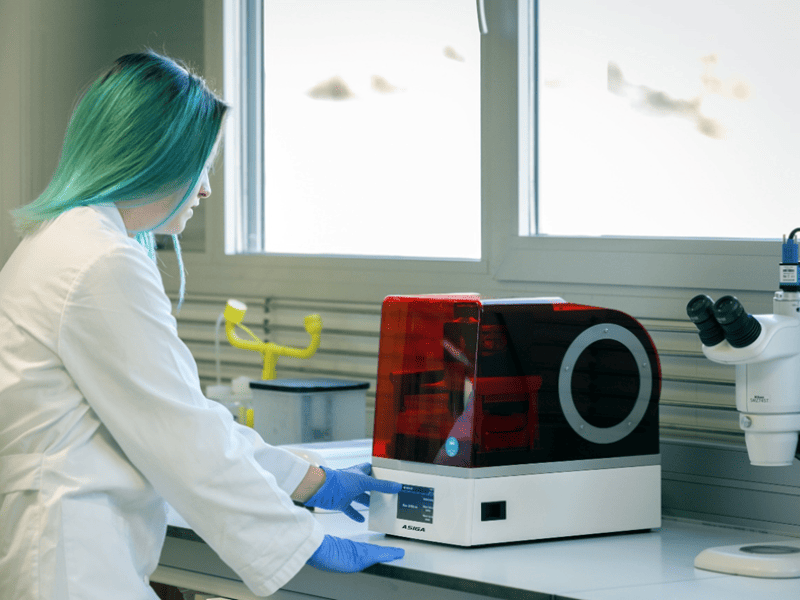

3D printing

Our cutting-edge laser-based 3D printing equipment allows us to prototype your design in hours with micrometric resolution. This innovative technology allows the production of complex microfluidic prototypes with internal channels and rapidly produce 3D molds polymer casting. We can create your device using biocompatible resins or other materials of different stiffness, flexibility, melting temperature and color depending on the final application.

Injection molding

With over a decade of experience in designing and simulating plastic injection molds, we are your go-to experts for injection mold design for top-quality devices. Contact our team to get started.

Mass production

All of Beonchip’s products are manufactured using plastic injection, micromachining, and bonding processes that are compatible with biomedical applications. If your company requires medium to high volume production of microfluidic devices, we can handle the manufacturing aspect of the project, allowing you to focus on sales.